If you're planning home renovations in the UK, you've probably heard the term "RSJ" mentioned by builders, architects, or structural engineers. But what exactly is an RSJ, and why is it such a common feature in British construction projects? This comprehensive guide explains everything UK homeowners and builders need to know about RSJs, from their basic definition to practical applications in modern building projects.

What Does RSJ Stand For?

RSJ stands for "Rolled Steel Joist" – a type of structural steel beam that has been a cornerstone of UK construction for over a century. The name refers to the manufacturing process where steel is heated and rolled into shape, creating the distinctive I-beam profile that most people associate with structural steelwork.

The Classic I-Beam Design

RSJs are characterised by their distinctive cross-sectional shape:

- Top flange: The horizontal section at the top

- Web: The vertical section in the middle

- Bottom flange: The horizontal section at the bottom

This I-shaped profile provides exceptional strength-to-weight ratio, making RSJs incredibly efficient for supporting loads across spans.

RSJ vs Universal Beams: Understanding the Difference

While "RSJ" remains widely used terminology in the UK, it's worth noting that modern steel beams are typically "Universal Beams" (UBs) rather than traditional rolled steel joists. Here's the distinction:

Traditional RSJs

- Tapered flanges (thicker at the web, thinner at the edges)

- Manufactured using older rolling techniques

- Still available but less commonly specified

Universal Beams (UBs)

- Parallel flanges (consistent thickness throughout)

- More efficient manufacturing process

- Better load distribution properties

- Standard specification in modern construction

In practice, many professionals still use "RSJ" as a general term for structural steel beams, regardless of whether they're technically Universal Beams.

Common RSJ Applications in UK Buildings

Residential Projects

Knock-Through Walls RSJs are essential when removing load-bearing walls to create open-plan living spaces. They carry the structural load that the wall previously supported.

Loft Conversions Converting roof spaces often requires RSJs to support new floor structures and distribute loads safely to existing walls.

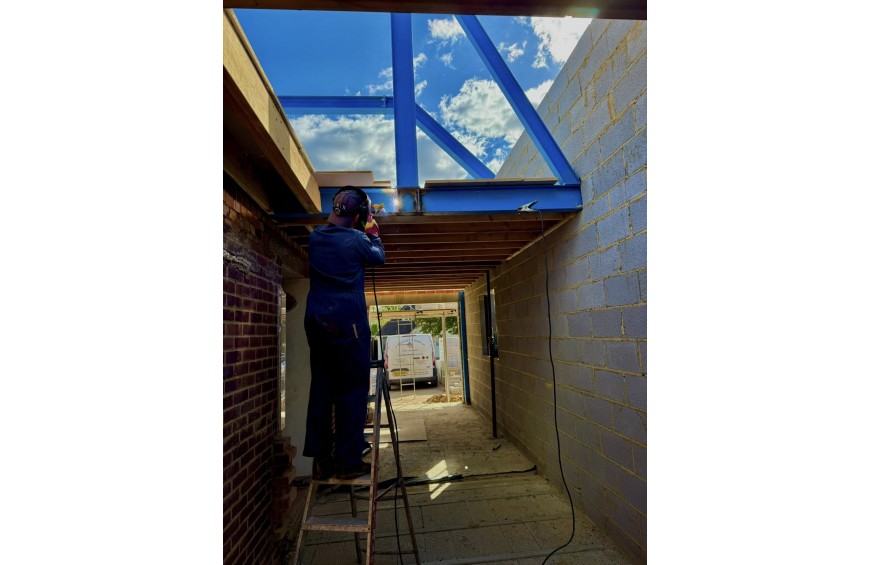

Extensions Single and double-storey extensions frequently use RSJs for spanning openings and supporting upper floors.

Basement Conversions Underpinning and structural modifications in basement projects commonly involve RSJ installation.

Commercial Applications

Office Fit-Outs Creating flexible commercial spaces often requires RSJs to span large areas without intermediate support columns.

Retail Conversions Converting buildings for retail use may require RSJs to create appropriate ceiling heights and floor layouts.

Industrial Buildings Warehouses, workshops, and manufacturing facilities rely heavily on RSJ framework for their structural integrity.

RSJ Sizes and Specifications

Standard UK Sizes

RSJs are specified using a standardised format: depth x width x weight per metre. Common residential sizes include:

Small Spans (up to 3m)

- 152 x 89 x 16kg/m

- 178 x 102 x 19kg/m

Medium Spans (3-5m)

- 203 x 102 x 23kg/m

- 254 x 102 x 25kg/m

Large Spans (5-7m+)

- 305 x 102 x 33kg/m

- 356 x 127 x 39kg/m

Factors Affecting Size Selection

Span Length The distance the RSJ must bridge without intermediate support is the primary factor in size selection.

Load Requirements

- Dead loads (permanent fixtures like floors, walls, roof)

- Live loads (furniture, occupants, stored materials)

- Special loads (snow, wind, equipment)

Deflection Limits Building regulations specify maximum allowable deflection (bending) under load.

Connection Requirements How the RSJ connects to existing structure affects size and specification.

The RSJ Installation Process

Pre-Installation Requirements

Structural Engineering A chartered structural engineer must calculate the appropriate RSJ size and specify connection details.

Building Control Approval Most RSJ installations require building control approval under UK Building Regulations.

Temporary Support Existing loads must be temporarily supported during installation using props and needles.

Installation Steps

- Preparation: Setting up temporary support systems

- Opening Creation: Cutting openings in walls for RSJ placement

- RSJ Positioning: Carefully manoeuvring the beam into position

- Connection: Securing the RSJ using specified connection methods

- Load Transfer: Gradually transferring loads from temporary to permanent support

- Finishing: Making good around the installation

Health and Safety Considerations

RSJ installation involves significant safety risks:

- Heavy lifting requiring mechanical aids or cranes

- Temporary structural instability during installation

- Working at height and in confined spaces

- Coordination between multiple trades

Building Regulations and RSJs

Part A: Structure

UK Building Regulations Part A covers structural safety requirements for RSJ installations:

Design Standards RSJs must be designed to British Standards (BS) and Eurocodes for structural steel.

Load Calculations Proper analysis of all loads the RSJ will carry throughout its service life.

Connection Design Appropriate connection methods to ensure loads are safely transferred to supporting structure.

Durability Consideration of environmental conditions and protection against corrosion.

Planning Permission

While RSJ installation itself rarely requires planning permission, associated work might:

- External alterations affecting building appearance

- Extensions exceeding permitted development rights

- Work to listed buildings or in conservation areas

Cost Considerations for RSJs

Material Costs

RSJ prices vary based on:

- Size and length: Larger beams cost significantly more

- Steel grade: Higher strength grades command premium prices

- Market conditions: Steel prices fluctuate with global commodity markets

- Quantity: Bulk orders may attract discounts

Typical price ranges (excluding installation):

- Small RSJs (under 3m span): £50-£150 per beam

- Medium RSJs (3-5m span): £150-£400 per beam

- Large RSJs (5m+ span): £400-£1,000+ per beam

Installation Costs

Professional installation typically costs:

- Basic installation: £500-£1,500 per beam

- Complex installations: £1,500-£5,000+ per beam

Factors affecting installation cost:

- Accessibility and working conditions

- Temporary support requirements

- Connection complexity

- Site location and logistics

Additional Costs

Don't forget to budget for:

- Structural engineering fees (£1,000-£3,000)

- Building control fees (£300-£800)

- Temporary accommodation if required

- Making good and decoration after installation

Advantages of RSJs

Structural Benefits

High Strength-to-Weight Ratio RSJs provide excellent load-bearing capacity while remaining relatively lightweight compared to alternative materials.

Versatility Suitable for a wide range of spans and loading conditions in residential and commercial applications.

Precision Manufactured to tight tolerances, ensuring predictable performance and easy installation.

Durability When properly specified and protected, RSJs can last for decades with minimal maintenance.

Practical Advantages

Space Efficiency The I-beam profile maximises structural efficiency while minimising the space occupied by the beam.

Integration RSJs can be easily incorporated into most building designs and construction methods.

Availability Standard sizes are readily available throughout the UK from steel stockholders.

Proven Track Record Decades of successful use in UK construction provide confidence in performance.

Potential Drawbacks and Considerations

Limitations

Fire Resistance Steel loses strength rapidly when exposed to high temperatures, often requiring fire protection measures.

Corrosion Without proper protection, steel can corrode in damp or aggressive environments.

Thermal Movement Steel expands and contracts with temperature changes, which must be accommodated in design.

Acoustic Performance Steel beams can transmit sound and vibration if not properly isolated.

Design Considerations

Headroom RSJs reduce ceiling height, which may be problematic in properties with limited headroom.

Services Integration Electrical and plumbing services may need to be rerouted around RSJ installations.

Aesthetics Exposed RSJs may not suit all architectural styles, though they can be boxed in or decorated.

RSJ Alternatives

Concrete Beams

Precast Concrete

- Higher fire resistance

- Better acoustic performance

- Heavier and more difficult to handle

In-Situ Concrete

- Can be formed to exact requirements

- Requires formwork and curing time

- Weather-dependent installation

Engineered Timber

Glulam Beams

- Renewable material

- Good strength-to-weight ratio

- May require treatment for durability

LVL (Laminated Veneer Lumber)

- Consistent performance

- Good for repetitive applications

- Limited span capability compared to steel

Composite Materials

Steel-Concrete Composite

- Combines benefits of both materials

- More complex design and installation

- Suitable for longer spans

Choosing the Right Professional

Structural Engineers

Look for professionals who are:

- Chartered with the Institution of Structural Engineers (IStructE)

- Experienced in residential/commercial work as appropriate

- Familiar with local building control processes

- Able to provide professional indemnity insurance

Contractors and Steel Erectors

Essential qualities include:

- Relevant experience with RSJ installation

- Appropriate insurance cover

- Good safety record and procedures

- Positive references from recent clients

Steel Suppliers

Choose suppliers offering:

- Quality certified materials

- Reliable delivery schedules

- Technical support and advice

- Competitive pricing

Future Trends and Innovations

Sustainable Steel

The steel industry is increasingly focused on sustainability:

- Higher recycled content in new steel production

- Improved energy efficiency in manufacturing

- Development of low-carbon steel alternatives

Advanced Coatings

New protective coatings offer:

- Extended service life

- Reduced maintenance requirements

- Better environmental performance

Digital Design Tools

Modern engineering software enables:

- More accurate structural analysis

- Optimised beam sizing

- Better integration with building information modelling (BIM)

Conclusion

RSJs remain a fundamental component of UK construction, providing reliable and cost-effective solutions for a wide range of structural challenges. Whether you're planning a simple knock-through or a complex renovation project, understanding what RSJs are and how they work helps you make informed decisions about your building project.

The key to successful RSJ installation lies in proper professional consultation from the outset. A qualified structural engineer can assess your specific requirements, recommend appropriate solutions, and ensure compliance with building regulations.

While the terminology may be evolving (with Universal Beams technically replacing traditional RSJs), the principles remain the same: these structural steel elements provide the backbone for safe, efficient, and durable building modifications that meet modern UK construction standards.

Remember that RSJ installation is not a DIY project – it requires professional expertise, proper equipment, and regulatory approval. By working with qualified professionals from design through installation, you can ensure your project proceeds safely and successfully, providing decades of reliable service.

Submit comment Cancel Reply