Ordering steel beams for your building project seems straightforward until you realize how many details can go wrong. A beam that arrives too late, with the wrong finish, or without proper documentation can halt your entire project, creating expensive delays and frustration. Whether you're a builder managing client renovations or a homeowner tackling an extension yourself, asking the right questions before placing your order prevents these costly problems.

This practical guide covers the five essential questions you must ask steel fabricators before ordering, explaining why each matters and what answers you should expect. Get these details confirmed upfront, and your steel beams will arrive on time, correctly specified, and ready for smooth installation.

Question 1: What Is the Realistic Lead Time, and What Could Delay It?

Understanding exactly when your steel will arrive—and what might affect this timeline—is crucial for coordinating other trades and maintaining project momentum.

Why This Question Matters

Your entire project schedule depends on steel arriving when expected. Builders schedule groundworks, install padstones or steel supports, arrange crane hire, and book follow-on trades based on anticipated steel delivery dates. When steel arrives late, every subsequent activity shifts, costing you money in wasted time, rescheduling fees, and extended equipment hire.

Conversely, steel arriving significantly early creates storage problems, exposes components to potential damage on busy sites, and ties up capital in materials sitting unused. Accurate delivery timing matters in both directions.

What to Ask Specifically

Don't accept vague answers like "about three weeks" or "pretty quick." Pin down specifics:

What is the lead time in working days from order confirmation to delivery? Get a number—10 working days, 15 working days, 20 working days—that you can plan around.

Does this lead time include or exclude material procurement? If the fabricator needs to order steel sections, does their quoted lead time start from when they receive materials or from when you place your order?

What size beams are you quoting for? Standard sections up to 356mm deep are usually readily available. Larger sections (457mm+) or less common sizes may require additional procurement time. Confirm the quoted lead time applies to your specific beam sizes.

Are there any current delays affecting fabrication? Busy periods (spring and summer construction seasons), supply chain issues, or workshop capacity constraints might extend standard lead times. Better to know now than discover this after ordering.

What surface treatment is included in the lead time? Basic shot blasting and primer typically adds 2-3 days. Intumescent fire protection adds 3-5 days. Hot-dip galvanizing adds 5-7 days as beams must be sent to specialist galvanizing plants. Ensure the quoted lead time includes all specified surface treatments.

What could cause delays beyond your control? Understanding potential issues—material shortages, galvanizing plant backlogs, delivery driver availability—helps you assess timeline reliability and plan contingency.

Red Flags to Watch For

Fabricators who can't or won't provide specific lead times raise immediate concerns. Quality fabricators track their workflow and know how quickly they can complete typical jobs.

Promises that seem too good to be true usually are. If most fabricators quote 15-20 days but one offers 7 days, question whether they truly understand your requirements or are promising unrealistic timelines to win your business.

Fabricators who blame everything on external factors—suppliers, galvanizers, delivery companies—without taking responsibility for coordinating these elements effectively suggest poor project management that will likely extend your timelines.

How to Plan Around Lead Times

Add buffer time to quoted lead times—typically 20-30% for standard work. If a fabricator quotes 15 working days, plan your schedule assuming 18-20 days. This buffer accommodates minor delays without derailing your entire project.

Order steel as early as possible once engineering drawings are approved and Building Control confirms your structural calculations. The earlier steel enters the fabrication queue, the less vulnerable you are to capacity issues or unexpected delays.

Communicate your project's critical dates clearly. If steel must arrive by a specific date for your project to proceed, tell the fabricator explicitly. They may be able to prioritize your work or flag if they cannot meet your required timeline.

Question 2: What Surface Finish and Protection Is Included, and What Are My Options?

Steel requires protective coatings to prevent corrosion and potentially to provide fire protection. Understanding exactly what's included in your quote and what alternatives exist ensures beams arrive properly protected for their intended use.

Why This Question Matters

Unprotected steel rusts quickly, especially when exposed to moisture during construction. Even brief periods without protection can cause surface corrosion that stains surrounding materials and compromises long-term durability.

Building Regulations frequently require fire protection for structural steel, with specific fire resistance periods depending on building height, use, and means of escape. Beams without adequate fire protection will fail Building Control inspection, halting your project until remedial work is completed.

Different environments require different protection levels. Internal steelwork in dry conditions needs less protection than external beams exposed to weather. Understanding your options helps you specify appropriate protection without over-specifying expensive coatings you don't need.

What to Ask Specifically

What surface preparation is included? Shot blasting is the industry standard, removing mill scale and contaminants while creating a surface profile for coating adhesion. Cheaper alternatives like wire brushing provide inferior results. Confirm your quote includes proper shot blasting to cleanliness grade Sa 2½.

What primer coating is included? Basic red oxide or zinc phosphate primers provide temporary protection during construction and a foundation for subsequent coatings. Confirm the primer thickness (typically 40-60 microns) and whether it's suitable for the environment your steel faces.

Is fire protection required, and if so, is it included? Check your structural engineer's drawings and Building Control requirements. Intumescent coatings providing 30, 60, or 90 minutes fire resistance represent significant additional costs—£30 to £60 per square meter of steel surface. Confirm whether fire protection is included or priced separately.

What are the options for enhanced protection? Hot-dip galvanizing provides decades of maintenance-free corrosion protection for external steelwork or aggressive environments. Multi-coat paint systems offer various protection levels and aesthetic finishes. Understanding options helps you specify appropriately.

Can you supply beams with just shot blasting if I'm arranging my own coating? Some projects benefit from beams shot blasted but not primed, allowing on-site application of specific coatings. Most fabricators can accommodate this, but confirm it's possible and whether it affects pricing.

How long will the supplied finish protect steel? Basic primer protects for several months during typical construction. If your project timeline is extended or beams will be stored outdoors, you might need enhanced temporary protection.

Common Finish Options Explained

Shot blasting and primer (standard for most internal steelwork): Provides several months protection during construction. Costs are typically included in basic fabrication charges.

Intumescent fire protection (required when specified by Building Regulations): Expands when heated to insulate steel during fires. Adds £30-£60 per square meter and 3-5 days to lead times. Available in various colors for aesthetic coordination.

Hot-dip galvanizing (for external steelwork or long-term protection): Provides 40-60 years of maintenance-free protection. Adds £400-£800 per tonne and 5-7 days to lead times. Results in characteristic gray spangled appearance.

Multi-coat paint systems (for aesthetics or specific environments): Two or three-coat systems in various colors. Adds £20-£40 per square meter depending on specification. Requires proper surface preparation and suitable drying conditions.

Weathering steel (Cor-Ten) (architectural applications): Develops stable rust-like patina that protects underlying steel. Requires specific steel grade and careful detailing. Premium cost over standard structural steel.

Understanding the Costs

Don't assume basic pricing includes everything you need. Many fabricator quotes include only shot blasting and primer, with fire protection, galvanizing, or decorative coatings priced separately.

Request itemized pricing showing material costs, basic fabrication, and each coating option separately. This transparency helps you understand cost drivers and make informed decisions about protection levels.

Fire protection significantly affects total costs. A beam requiring 60-minute intumescent coating might cost £800 in basic form but £1,200-£1,400 with fire protection included. Factor this into your budget from the outset.

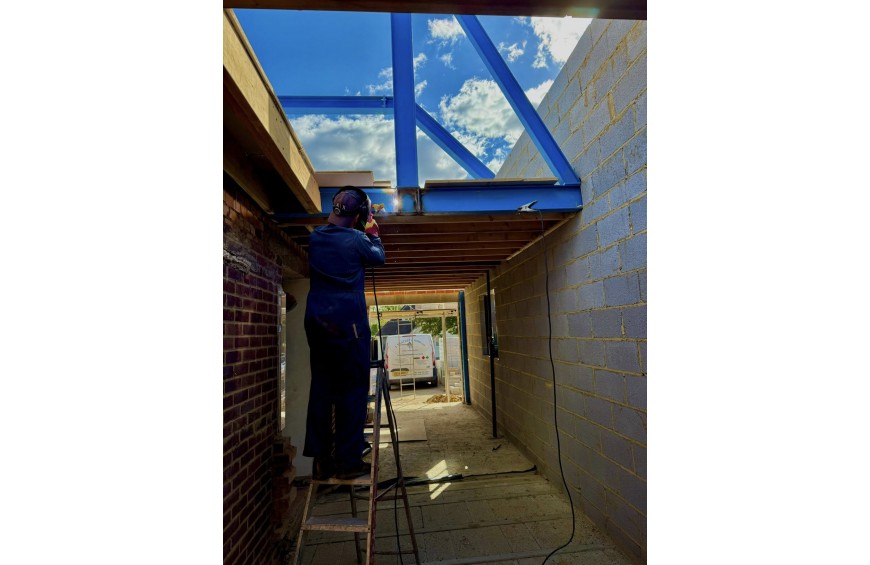

Question 3: What Support and Bearing Requirements Must I Prepare Before Delivery?

Steel beams can't simply be dropped into buildings—they require proper support at each end to safely transfer loads to the structure below. Understanding exactly what's needed before beams arrive prevents installation problems and structural inadequacy.

Why This Question Matters

Inadequately prepared bearing points create dangerous installation situations where beams can't be properly supported, forcing improvised solutions that compromise structural integrity. Your structural engineer's calculations assume beams bear on supports of specific dimensions—deviations from these specifications invalidate the engineering.

Preparing padstones, pocket formations, or steel column caps requires time and must be completed before steel delivery. Discovering you need 100mm bearing when you've only prepared 75mm halts installation, creating expensive delays while remedial work is completed.

Different bearing types suit different situations. Understanding your options helps you coordinate with your structural engineer and prepare appropriate support details.

What to Ask Specifically

What bearing length is required at each end? This critical dimension determines how much of the beam must sit on supporting structures. Typical residential beams require 100-150mm bearing on masonry walls or 75-100mm on padstones.

What is the vertical load and bearing pressure? Your groundworks or masonry must be designed to safely carry the forces the beam transfers. Bearing pressure (typically measured in Newtons per square millimeter) determines padstone size and foundation requirements.

Are there any specific requirements for beam orientation or positioning? Some beams must be installed in specific orientations. Others have offset bearing requirements where beam centerlines don't align with support centerlines. Clarify these details before preparing supports.

What tolerance exists for bearing position accuracy? Understand how precisely supports must be positioned. Typical tolerances are ±10mm for horizontal positioning and ±5mm for vertical positioning. Tighter tolerances require more careful preparation.

What happens if prepared bearings aren't exactly as specified? Knowing fabricator policies about site modifications or adaptations helps you understand the consequences of preparation errors. Some fabricators accommodate minor adjustments; others require exact compliance with specifications.

Can you provide detailed bearing drawings showing exactly what's required? Request drawings or sketches clearly showing beam positions, bearing dimensions, and any special requirements. These visual references prevent misunderstandings.

Common Bearing Types

Masonry wall pockets: Beams sit directly in recesses formed in masonry walls. Pockets must be sized to provide required bearing length plus small clearance for beam placement. Walls must be structurally adequate to carry concentrated loads.

Padstones: Concrete or dense masonry blocks distribute beam loads over larger wall areas. Padstones must be installed level, at correct height, and sized to prevent bearing pressure exceeding wall capacity. Typical residential padstones are 440×215×100mm or 600×215×140mm depending on loads.

Steel columns: Beams connect to vertical steel columns using various connection details. Column caps must be level and positioned accurately. Connection bolt holes must align with beam hole positions.

Goalpost arrangements: Two vertical posts support horizontal beams at room openings. Posts must be plumb, correctly spaced, and adequately founded. Cap plates on posts must be level and positioned to receive beam bearing.

Existing structure: When beams bear on existing floors or beams, these structures must be verified as adequate for additional loading. Structural engineers should confirm existing capacity before new beams are ordered.

Preparing Bearings Correctly

Start bearing preparation early, immediately after structural calculations are approved. Padstones require setting in mortar with time to cure before bearing loads. Wall pockets need forming as masonry progresses.

Verify bearing preparation using careful measurement. Check bearing heights with spirit levels and laser levels ensuring they're perfectly level—uneven bearings create installation problems and potential structural issues.

Confirm bearing positions match engineering drawings exactly. Measure from multiple reference points to ensure accuracy. Even small positioning errors can prevent beams from aligning correctly with structural openings.

Have your structural engineer or Building Control inspector verify bearing preparation before steel delivery. This inspection confirms everything is correct before beams arrive, preventing discoveries of problems when installation teams are on site.

Question 4: What Documentation Will You Provide, and Do I Need Anything Else for Building Control?

Building Control approval requires specific documentation proving steel components meet structural engineering specifications and Building Regulations requirements. Understanding what fabricators supply and what additional documents you need ensures smooth inspections.

Why This Question Matters

Building Control officers won't approve structural steelwork without proper documentation. Missing certificates or test reports halt projects while you track down required paperwork, creating delays that affect your entire schedule.

Some documentation comes from fabricators, while other documents must be obtained separately. Understanding who provides what prevents assumptions that leave gaps in your documentation package.

Quality fabricators provide comprehensive documentation as standard. Those who are reluctant or unclear about documentation may not maintain proper quality systems, raising concerns about their work quality generally.

What to Ask Specifically

Will you provide material certificates (mill certificates) for all steel supplied? These documents trace steel back to its production, confirming grade, chemical composition, and mechanical properties. Building Control requires these certificates for structural steel approval.

Do you hold EN 1090 certification for structural steelwork fabrication? This European standard demonstrates fabricators have appropriate quality management systems, qualified personnel, and suitable equipment. CE marking required for structural steel depends on EN 1090 certification.

Will CE marking documentation be included with delivery? CE marks confirm structural steel components meet harmonized European standards. Declaration of Performance documents must accompany CE-marked steelwork.

What welding procedure specifications and welder qualifications apply to this work? Structural welding requires procedures approved to BS EN ISO 15614 and welders qualified to BS EN ISO 9606. Fabricators should provide this documentation for Building Control inspection.

Will you provide coating thickness certificates if fire protection or specific coatings are specified? Intumescent coatings must achieve specified thicknesses to provide design fire resistance. Coating certificates document thickness measurements proving compliance.

Do you provide fabrication drawings showing as-built dimensions? These drawings confirm what was actually fabricated versus what was ordered. They're valuable records for building files and future reference.

What structural calculations or design certifications apply? Some fabricators provide design services including calculations. Clarify who is responsible for structural design and what documentation supports it.

Essential Documents for Building Control

Your complete Building Control submission package should include:

Structural calculations: Prepared by qualified structural engineers, demonstrating steel sections safely carry design loads with appropriate safety factors.

Structural drawings: Showing beam sizes, positions, connections, and all relevant details. These drawings guide fabrication and installation while providing approval documentation.

Material certificates: Confirming steel grade and properties meet specifications in structural calculations.

CE marking declarations: Demonstrating structural steelwork compliance with harmonized standards.

Fabrication certificates: Confirming fabricator qualifications, welding procedures, and quality control processes.

Fire protection certificates (if applicable): Documenting intumescent coating thickness and fire resistance periods achieved.

Installation records: Showing who installed steelwork, when it was installed, and confirming installation matched engineering drawings.

When Documentation Issues Arise

If fabricators can't or won't provide required documentation, this raises serious concerns. Structural steelwork without proper documentation may not satisfy Building Control even if the physical components are acceptable.

Some smaller fabricators lack formal EN 1090 certification but still produce quality work. Discuss this with Building Control before ordering—they may accept alternative evidence of fabricator competency in specific circumstances.

Never accept fabricators' assurances that documentation isn't necessary or that Building Control won't ask for it. Officers take documentation requirements seriously, and missing paperwork causes project delays you'll ultimately pay for.

Question 5: What Are Your Delivery Arrangements, and What Do I Need to Prepare On Site?

Understanding exactly how steel will be delivered and what site preparations you must make prevents delivery problems that can damage steel or create dangerous situations.

Why This Question Matters

Steel delivery vehicles are large—typically 12-18 meter articulated lorries or rigid trucks requiring significant access space for maneuvering and unloading. Sites with restricted access, narrow lanes, low bridges, or parking restrictions create delivery challenges that must be addressed before dispatch.

Inadequately prepared sites lead to delivery vehicles that can't access, beams that can't be unloaded safely, or damaged components from improper handling. These problems cost money and delay projects while solutions are arranged.

Most fabricators deliver using standard flat-bed lorries without cranes. Unless you specifically arrange otherwise, you're responsible for unloading equipment—mobile cranes, telehandlers, or forklift trucks—and qualified operators to use them safely.

What to Ask Specifically

What type and size of delivery vehicle will be used? Understand vehicle dimensions and maneuverability requirements. Typical articulated lorries are 16.5 meters long with 13.6 meter trailers. Rigid vehicles are shorter (around 12 meters) but carry less.

Does the delivery include unloading, or must I provide lifting equipment? Most standard deliveries are "kerbside"—drivers help guide loads but don't provide cranes. Hiab deliveries include lorry-mounted cranes for unloading but cost significantly more.

What advance notice will you provide before delivery? Fabricators should contact you 2-3 days before delivery confirming the date and approximate time. This notice allows you to arrange site access, notify neighbors if necessary, and have lifting equipment available.

What are the delivery vehicle's access requirements? Understand minimum road width, turning circles, overhead clearances (power lines, tree branches), and weight restrictions (weak bridges). Delivery drivers won't risk getting stuck or causing damage.

Where will the driver expect to unload? Delivery vehicles need flat, firm standing for safe unloading. Soft ground, steep slopes, or inadequate turning space create problems. Discuss site conditions honestly so appropriate vehicles can be scheduled.

What happens if delivery can't be completed due to site access problems? Understand policies on aborted deliveries. Many fabricators charge return fees (£200-£400) if vehicles can't access sites through no fault of their own.

How will beams be packaged and protected? Plastic wrapping protects painted surfaces during transport. Timber battens separate stacked components. Understanding packaging helps you plan handling and storage.

What weight are individual beams? Knowing beam weights helps you arrange appropriate lifting equipment. A 305x165x40 UB at 6 meters long weighs approximately 240kg—manageable with proper equipment but too heavy for manual handling.

Site Preparation Requirements

Clear access routes: Ensure delivery vehicles can access without damaging services, landscaping, or neighboring property. Remove or protect vulnerable items like fencing, gates, or parked vehicles.

Arrange lifting equipment: Book mobile cranes or telehandlers for the delivery day. Provide operators with beam weights and dimensions so they can confirm equipment capacity adequacy.

Designate unloading areas: Identify safe locations for placing beams, whether for immediate installation or temporary storage. Areas should be level, firm, and clear of obstructions.

Brief site personnel: Ensure everyone on site understands delivery timing and stays clear of unloading operations. Steel beams being craned into position create serious hazards for unaware persons.

Check access restrictions: Verify there are no parking restrictions, road closures, or events that might prevent delivery vehicle access on scheduled dates.

Weather considerations: Heavy rain, ice, or snow can make unloading dangerous and may require delivery rescheduling. Discuss contingency plans with fabricators.

Common Delivery Issues and Solutions

Access width restrictions: Narrow lanes that standard articulated lorries can't navigate require smaller rigid vehicles. These carry less, potentially requiring multiple deliveries at additional cost. Plan ahead for access limitations.

Bridge weight limits: Light bridges on access routes can't support fully loaded steel delivery vehicles. Arrange deliveries when vehicles are partially loaded or identify alternative routes.

Overhead obstructions: Power lines, tree branches, or low bridges prevent crane operations needed to unload long beams. Survey access routes beforehand identifying any height restrictions.

Temporary road closures: Urban roadworks or events can block access on delivery days. Maintain communication with fabricators allowing deliveries to be rescheduled if access issues emerge.

Inadequate ground conditions: Soft or uneven ground where delivery vehicles must park creates tipping hazards. Install temporary matting or hardcore to stabilize ground if necessary.

Bonus Considerations: Additional Questions Worth Asking

Beyond the five essential questions, several other considerations merit discussion before finalizing your steel order.

What Warranties or Guarantees Do You Provide?

Reputable fabricators stand behind their work, offering warranties on fabrication quality, dimensional accuracy, and coating performance. Understand what's covered, for how long, and what remedies exist if problems arise.

Typical warranties cover fabrication defects for 12 months from delivery. Coating warranties vary—primers might be covered for 6 months, while galvanizing might carry 25-year guarantees against perforation.

Can You Provide References from Similar Recent Projects?

Speaking with previous clients provides insights into fabricator reliability, quality, communication, and problem-solving when issues arise. Any hesitation about providing references raises concerns.

Ask references specific questions: Did steel arrive when promised? Was fabrication quality acceptable? Did Building Control raise any issues with documentation? Would they use this fabricator again?

What Happens If Components Don't Fit During Installation?

Despite best efforts, occasionally fabricated components don't fit as expected due to site variations, measurement errors, or fabrication issues. Understanding fabricator policies about remedial work prevents disputes when problems occur.

Quality fabricators rectify genuine fabrication errors at their cost. Site-related issues or design changes after fabrication may incur additional charges. Clear policies prevent misunderstandings.

Do You Offer Installation Services or Can You Recommend Installers?

Some fabricators provide complete supply-and-install packages. Others focus purely on fabrication but maintain relationships with trusted installation contractors they can recommend.

Integrated packages simplify project management and create clear responsibility lines. However, they may cost more than arranging separate supply and installation. Evaluate options based on your specific project needs.

What Payment Terms Apply?

Understanding when payment is due—deposits on order, stage payments during fabrication, or payment on delivery—helps you plan cash flow and protects both parties.

Many fabricators require 30-50% deposits on order, with balances due on delivery or within 30 days. Clarify terms upfront to avoid surprises and ensure they work for your financial planning.

Putting It All Together: Your Pre-Order Checklist

Before confirming any steel beam order, ensure you can answer yes to these critical questions:

☐ I know exactly when steel will be delivered (specific working days)

☐ I understand what surface finishes are included and whether they're adequate for my project

☐ I know what bearing support requirements must be prepared before delivery

☐ I've confirmed what documentation will be provided and verified it satisfies Building Control

☐ I've assessed site access and arranged appropriate unloading equipment

☐ I've received clear written quotations itemizing all costs

☐ I've verified fabricator credentials including EN 1090 certification

☐ I've confirmed my structural engineer's drawings are complete and approved

☐ I've coordinated delivery timing with other project activities

☐ I understand what warranties apply and what happens if problems arise

Conclusion

Ordering steel beams successfully requires asking specific questions about lead times, surface finishes, bearing requirements, documentation, and delivery logistics. These five essential questions—and their various sub-questions—provide the information you need to coordinate your project effectively, satisfy Building Control requirements, and ensure steel beams arrive correctly specified and ready for installation.

Don't accept vague answers or assumptions. Pin fabricators down on specifics, get everything confirmed in writing, and verify that their responses align with your structural engineer's requirements and your project needs. The few minutes spent asking these questions before ordering prevents the hours or days of problems that unclear specifications create.

Quality fabricators welcome detailed questions—they indicate serious, organized clients who understand what's required. Fabricators who seem impatient with questions or unable to provide clear answers raise concerns about their professionalism and whether they're the right partner for your project.

Your steel beams are critical structural components supporting significant building loads. Ensuring they're correctly specified, properly fabricated, adequately documented, and delivered when needed protects your project timeline, budget, and ultimately the safety and performance of your completed building. Ask these five essential questions before every steel order, and you'll have the information needed to make informed decisions and coordinate successful steel installations.

Submit comment Cancel Reply